THE PHASES OF A LANDFILL

The landfill is a method that provides for the final disposal of waste by superimposed layers, in order to facilitate the fermentation of the organic matter. The processes of decomposition of organic substances that occur by anaerobic bacteria present in landfills lead to the production of leachate and biogas, the disclosure of which would be in the environment due to pollution of soil, water (surface and groundwater) and air .

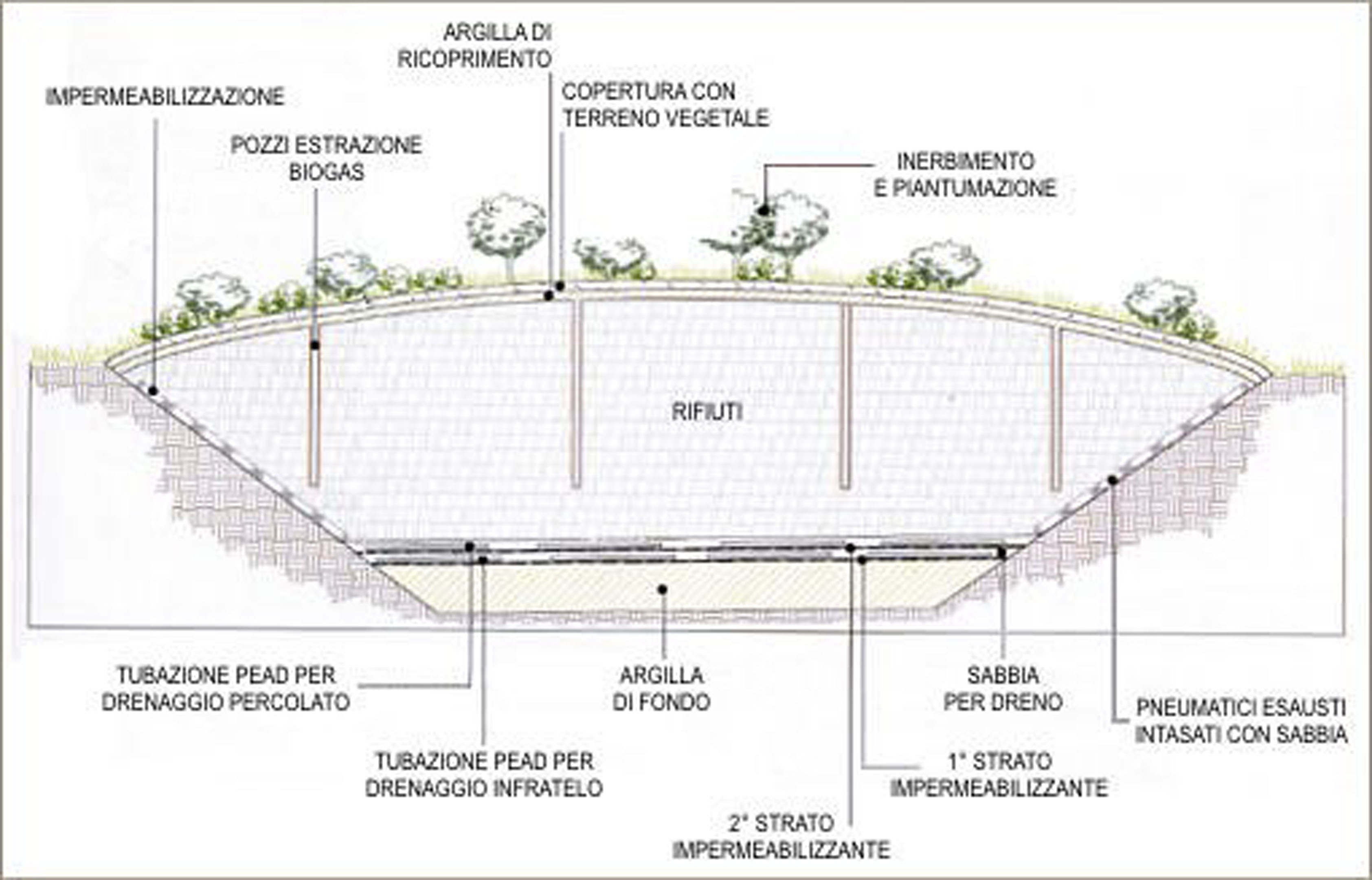

Thus, the criteria for the construction of a controlled dump must ensure the limitation of the flow of pollutants towards the external environment (for example, through the realization of barriers waterproofing, drainage systems of the leachate and of collection wells of biogas).

Other problems that need to be addressed in the construction of a landfill are the conditions of stability and settling of the body of waste, the problems of stability of the ground support, slope and retaining structures (dams) and the activities of final settlement and recovery of the area occupied by the landfill.

• Landfills depression (or trench) are designed for filling old abandoned quarries or "was" specially dug in the ground;

• Landfills detected: rest at the ground level and grow in height;

• Landfills slope: they are made close to the slopes, to fill open patches along the sides due to quarries, ravines areas or watersheds.

LANDFILL CONTROLLED

Controlling the spread of the products of biodegradation that occurs in landfills (biogas and leachate) requires the presence of low-permeability barriers. These barriers can be of natural origin, that is made up of layers of soil containing clay, were already there or are specially placed and compacted.

Often, however, the clayey material is not available; in these cases, you must use of artificial impermeable barriers, either alone or in addition to clay soil.

Landfills for municipal waste may be equipped with a system of drainage and leachate collection. In fact, the liquid fraction pollutant that forms as a result of biodegradation processes in the landfill collects in pockets between the various levels of waste stored, and then would tend, in the absence of further interventions, to escape from the banks or accumulate at the bottom.

The ducts leachate collection are inserted in a very permeable drainage layer, disposed above the impermeable base and directed towards a collecting well.

From the sump, the leachate is removed by means of a pump and conveyed into a settling tank, from which it is sent for processing to a purification plant, which may be internal or external.

LANDFILL FINAL SETTLEMENT

The final settlement of the landfill has the following objectives:

- Reduction of infiltration of rainwater surface, to contain the production of leachate;

- Leakage checking of biogas into the atmosphere;

- Retrieving a green area.

The draft covering must take into account the type of material available, the type of waste planted, potential adjustments within the body of the landfill and the characteristics of the site (the values of precipitation and the performance of the original topography and the final one, which can give indications on the main directions of flow of runoff).

The soil plant should be selected based on the type, the content of nutrients, at the levels of pH ( optimum when it is equal to about 6.5, that is, slightly acid, so as to counteract the action of evaporation of leachate that in the closed landfills is slightly basic), the local climatic conditions and plant species provided.

The last phase of the arrangement of the area of landfill consists in planting, which must be made taking into account, in addition to the real and potential vegetation area, also the uncomfortable conditions of media. In fact, the mortality of the species planted landfill is very high, due to immaturity of the land used, irregular drainage water and suffocation of the roots caused by gas leaks are not perfectly collected by the suction system.

BIOGAS FROM THE LANDFILL

Biogas plants installed at municipal waste landfills give a good contribution to the production of clean energy and help reduce greenhouse gas emissions into the atmosphere.

The biogas, which is formed by the process of degradation of the organic component of waste, is intercepted by more extraction wells, evenly distributed over the entire area of the landfill, and started to combustion in special gas engines internal combustion.

The motors transform the calorific value of the biogas into mechanical energy and then, due to a generator, into electric energy. In many cases, in addition to the engine these installations are also equipped with a system of heat recovery, for the simultaneous production of electricity and heat in cogeneration mode.

The biogas produced in excess of the capacity of the plant is burned by torches. These torches are used to destroy some dangerous pollutant compounds inevitably they release CO2 into the atmosphere.

Enhance the biogas through the production of electricity or through the cogeneration of electricity and heat, is in most cases the best technical and economical choice.

LEACHATE TREATMENTEQUIPMENT AND SOLUTIONS

The leachate is a liquid that has mainly derive from the infiltration of rainwater into the mass of waste or by the decomposition of the same. To a lesser extent is also produced by the progressive compaction of waste. The leachate produced by the landfill of municipal solid waste (MSW) is a wastewater with a higher or lower content of organic and inorganic pollutants, arising from the physico-chemical and biological processes within the landfill. By law, the leachate must be collected and properly treated in the same site of the landfill or transported in ad hoc systems.

TECHNOLOGY: ULTRAFILTRATION + REVERSE OSMOSIS:

The leachate undergoes an initial treatment of clear-flocculation for the removal of metals and suspended solids. Subsequently it is filtered on quartzite for a complete clarification and finally reaches the plant of microfiltration / ultrafiltration. The next stage is the treatment by reverse osmosis, for the reduction of the salts present. The ammonia is removed by osmosis, after salting. Any residual phenols are removed by oxidation and final filtration with activated carbon. The leachate concentrate can be fed back into landfill or be disposed externally.

TECHNOLOGY: REVERSE OSMOSIS + CONCENTRATION :

The leachate undergoes a first evaporation treatment with which is obtained a concentrate will be sent again landfill and a distillate that is treated for the reduction of ammonia. The ammonia is removed by osmosis, after salting. Any residual phenols are removed by oxidation and final filtration with activated carbon. In the case in which the leachate concentrate can not be fed back in landfills and must therefore be disposed externally, before the concentration treatment, is carried out a treatment of clear-flocculation for the elimination of heavy metals. This system will allow you to dispose of a concentrated leachate metal-free and thus save on disposal costs.